Sugarcane Fiber Mat

Sugarcane fibre is a natural fibre which has wide range of uses in handicraft or other types of product developments such as mat rope food plate but with adding some resin materials and we can get a new product.

Sugarcane fiber mat. Used for 2 d 3 d screw cotton pp cotton doll cotton ordinary hollow cotton are evenly scattered fleeciness just need one time opening opening rate up to 96. Find types of banana fiber with prices in india. Technology parameter of cotton filling machine. Isocyanate lecopol e0911 in a ratio of 1 1 50 polyol and 50 isocyanate.

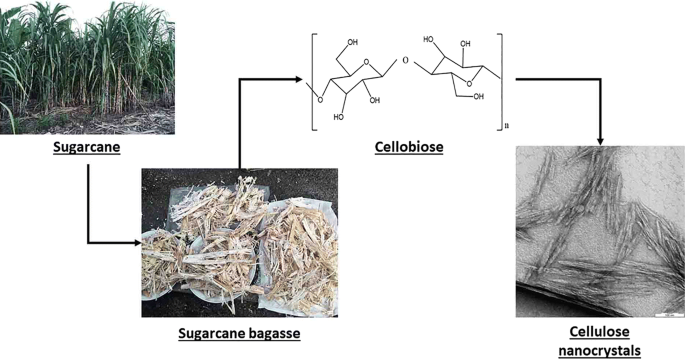

Model fr 200 fr 100 motor power 1 5kw 1 5kw air pressor 0 7 0 8mpa 0 7 0 8mpa c otton mouth number 2 1 dimension 1200 900 1600 1700 800 1200mm polyester fiber machine as following. The pu resin used was the bi component castor oil polyurethane polyol lecopol e0921. In this work sugarcane fiber composites were obtained and subjected to mechanical recycling. The green coconut fiber and sugarcane bagasse fiber used for the production of the multilayer particleboards were sourced locally from brazilian processing companies.

Sugarcane fibers are a renewable resource. As it has a property like weatherproof uv protection moisture absorption. Find manufacturer suppliers exporters wholesalers of banana fiber with contact details address across india. About 23 of these are other tableware.

The samples composites and polypropylene plates were cut and submitted. Incepted in the year 2015 we tmks agro products are one of the renowned manufacturers of banana fiber banana fiber yarn grass yoga mat basic foam yoga mat etc. Investigation conducted by mendes and cestari 2011 on utilization of cellulose polarity as vehicle for receiving and retaining ink thus enabling the feasibility of continuous polymeric matrix hdpe highly filled with sugarcane bagasse fiber scb as an ink absorbing material found that i the ground scb fiber can pass through 20 40 and100 mesh sieve as they are small enough to present. Better mixer method for fiber sugarcane bagasse bagasse cellulose and benzy lated bagasse and m atrix polypropylene.

The use of natural fibers may promote good mechanical properties low abrasion low energy consumption during preparation and lower costs compared with synthetic fibers. We have established a world class infrastructure facility that encompasses machines and equipment that are based on the modern and advanced technologies.