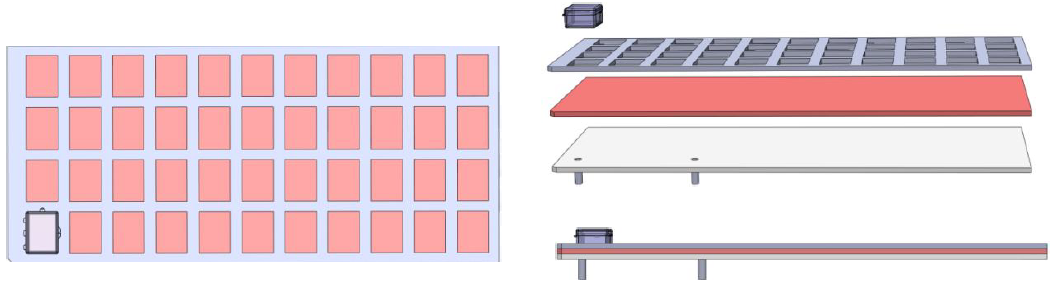

Tacky Mat Fixture For Printer Part Positioning

It can easily be removed and reinstalled by placing it in position and gently pressi.

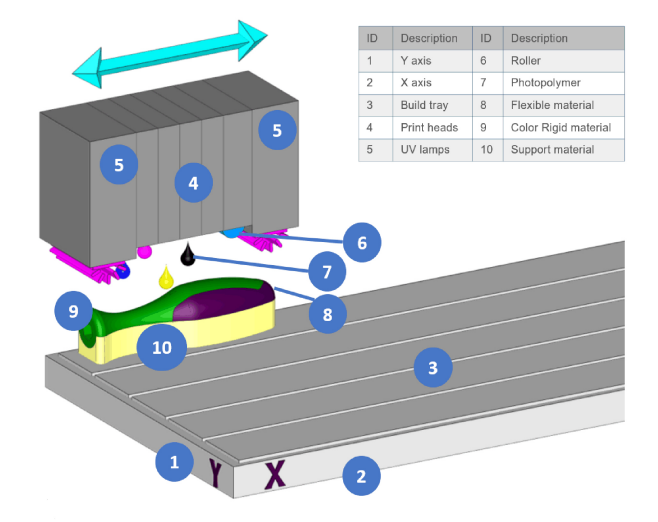

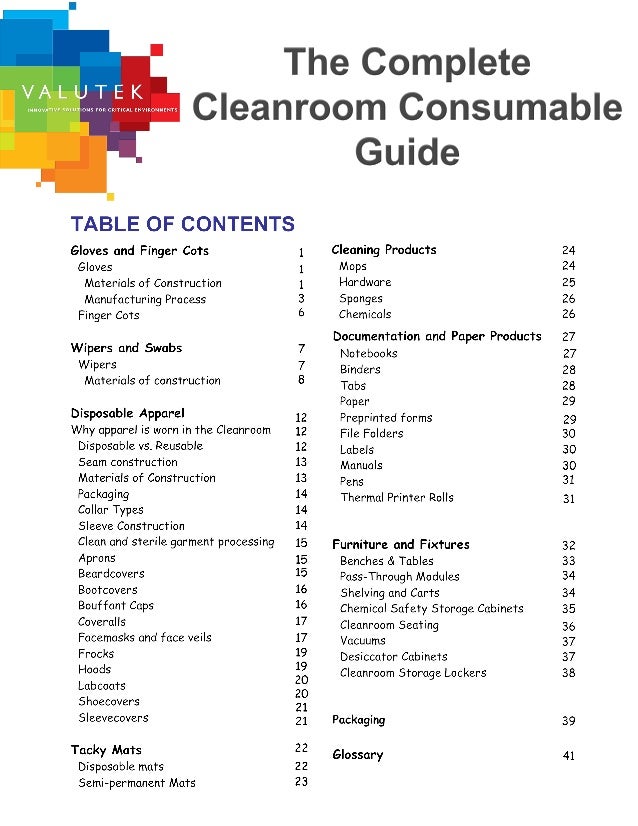

Tacky mat fixture for printer part positioning. These mats are easy to install and maintain at entrances to data centres cleanrooms and other controlled environments. Valutek sticky mat for cleanrooms adhesive tacky mat removes dust dirt small debris up to 3 microns size 24 x 36 120 sheets 4 pads of 30 sheets blue 4 4 out of 5 stars 133 49 90 49. Tacky mats are designed to capture particles from foot traffic and equipment wheels providing the most effective and convenient dirt removal method available. Typically manufacturers machine tooling in metal either in house or through outsourced vendors.

While you may be able to set your browser to block or alert you about these cookies some parts of the website will not function without them. After a 3d print is finished the top two sheets easily slide away from the print bed and with a twist the part releases cleanly. What to do with the nmfc code after you ve located it. Jigs and fixtures are used to make manufacturing and assembly processes simpler and more reliable reducing cycle times and improving worker safety.

What to do if you can t find the nmfc code you need. Tacky traxx mats sometimes referred to as tacky mats are multi layered adhesive mats designed to remove dirt and other particulate from foot and cart traffic upon entrance into a cleanroom or clean area. Available in many sizes to fit all kinds of 3d printers simply add the magnetic base on top of the existing print bed and the flexplate with attached buildtak sheet will magnetically connect. Each mat contains 30 individually numbered sheets that easily peel off revealing.

Browse a selection of cleanroom tacky mats from grainger. These mats feature a bright surface that makes it easy to identify when the top layer needs to be changed. Enter the nmfc code shown in the freight class lookup tool in the instant quote form on the right side of this page or in our full freight quote comparison tool. There are many ways jigs and fixtures are created and they have been used in making items since before the.

We are unable to turn these cookies off in the system. No double stick tapes vacuums or clamps are necessary. Depending on the forces experienced by the part however it may not always be necessary to produce these tools in metal. Jigs and fixtures are often used in manufacturing for a number of different reasons but mainly to ensure repeatability and accuracy in a manufacturing process and to hold items in a fixed position during manufacturing.

90 12 48 mats 65 25 65 25.