Technical Ceramic Composition

Usually they are metal oxides that is compounds of metallic elements and oxygen but many ceramics especially advanced ceramics are compounds of metallic elements and carbon nitrogen or sulfur.

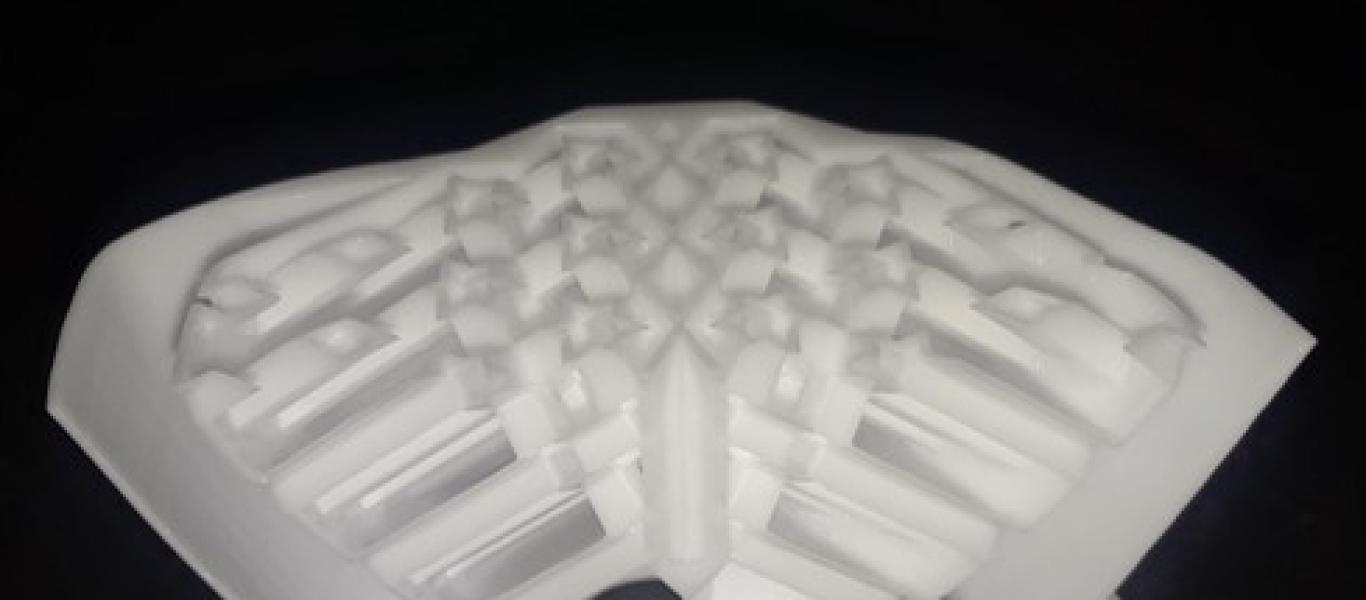

Technical ceramic composition. Polycrystalline ceramics are solids in which the atoms or ions are arranged in regular array. Silicate ceramics oxide ceramics non oxide ceramics and piezo ceramics. By choosing and adjusting the suitable material composition the material can be perfectly adapted to the ambient conditions. Some elements such as carbon or silicon may be considered ceramics.

Industrial ceramics are commonly understood to be all industrially used materials that are inorganic nonmetallic solids. Ceramic composition and properties atomic and molecular nature of ceramic materials and their resulting characteristics and performance in industrial applications. In contrast the regularity order is only short range in glass amorphous materials because a glass is formed when a molten ceramic composition is rapidly cooled the atoms do not have time to arrange themselves in a periodic structure. As technical ceramics non metallic inorganic and partly crystalline materials are referred to which are applied in industry due to their specific properties rie08.

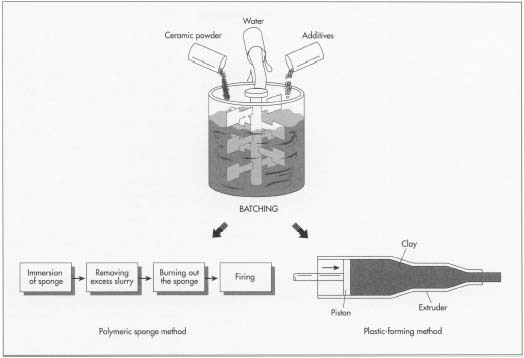

Technical ceramics from ceramtec can be divided into four major groups of ceramic materials. With technical ceramics these properties can be specifically modified and enhanced for specific cases. In contrast to classical ceramics no naturally occurring minerals but chemically prepared or synthetically produced starting materials are used whose composition can be. Silicate ceramics are the oldest type of ceramic materials for technical applications and are made primarily from natural raw materials in conjunction with alumina aluminum oxide aluminum silicate.