Temperature Dependence Of Ceramic Chip Capacitor

So for example the ever popular c0g has a temperature drift of 0 0 30 ppm c 25c to 85c and p3k has a temperature drift of 1500 250 ppm c.

Temperature dependence of ceramic chip capacitor. To manufacture a chip type smt and achieve miniaturization high density and. Tolerance only applies from 25c to 85c. The bx specification has voltage temperature limits in addition to temperature limits of capacitance. A rule of thumb is the higher the temperature dependence of the ceramic the higher the aging percentage.

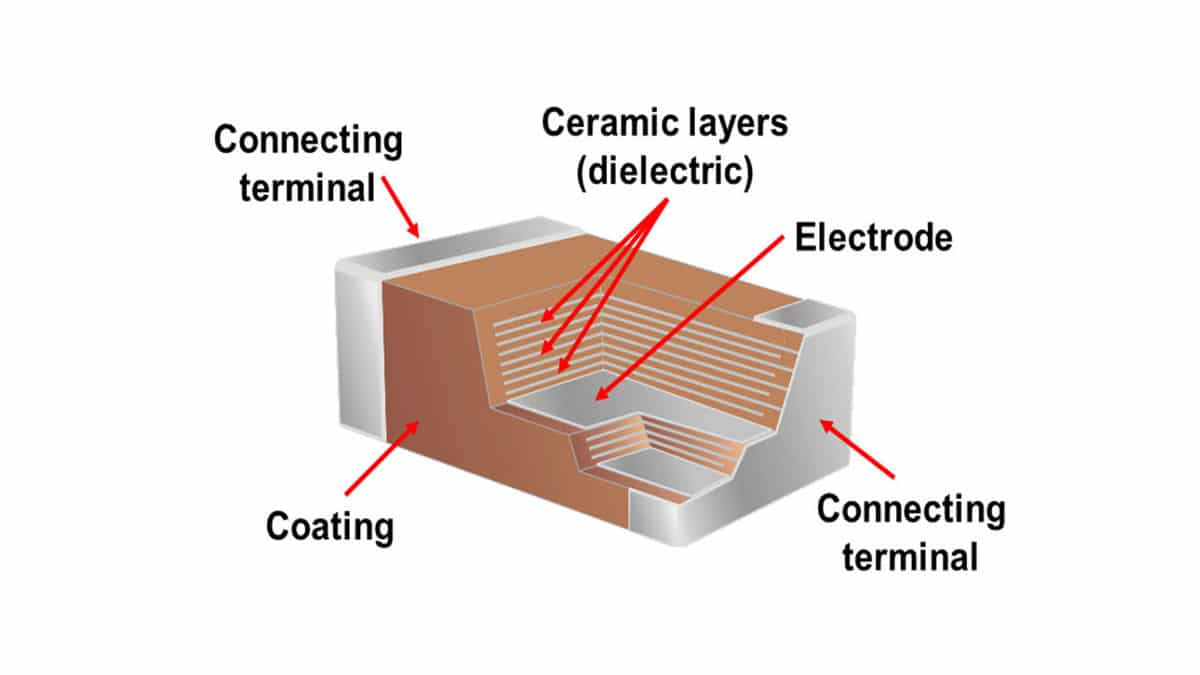

The two typical class ii categories x5r and x7r both have a maximum of 15 allowed change of capacitance with temperature in the temperature range of 55 to 85 and 55 to 125 degc respectively. The x2y ceramic chip capacitor however is a 4 terminal chip device. Multilayer ceramic capacitor 1 introduction mlcc is an electronic part that temporarily stores an electrical charge and is classified according to the rate of decay of capacity at a certain temperature. X7r formulations are called temperature stable ceramics and fall into eia class ii materials.

Electrical behavior of ceramic chip capacitors is strongly dependent on test conditions most notably temperature voltage and frequency. The military specification for ceramic chip capacitors mil prf 55681 defines a mid k stable dielectric designated as bx. This capacitance change is non linear. In a multilayer ceramic capacitor.

Table 1 shows eia rs 198 codes for class 1 ceramic capacitors and specifies temperature range and capacitance drift tolerance over that range. Prior to the selection of suitable ratings consider the factor of the temperature change inside the equipment. Class ii ceramics have a standardized window of allowed temperature dependence for each sub class. The temperature coefficient is expressed in parts per million ppm per degree celsius for class 1 ceramic capacitors or in percent over the total temperature range for class 2 capacitors.

Factors of the temperature change within the equipment 1 seasonal variation e g winter and summer. Mlcc consists of a conducting material and electrodes. The different dielectrics of the many capacitor types show great differences in temperature dependence. This dependence on test parameters is more evident with class ii ferroelectric dielectrics and negligible or more easily predictable with class i formulations.

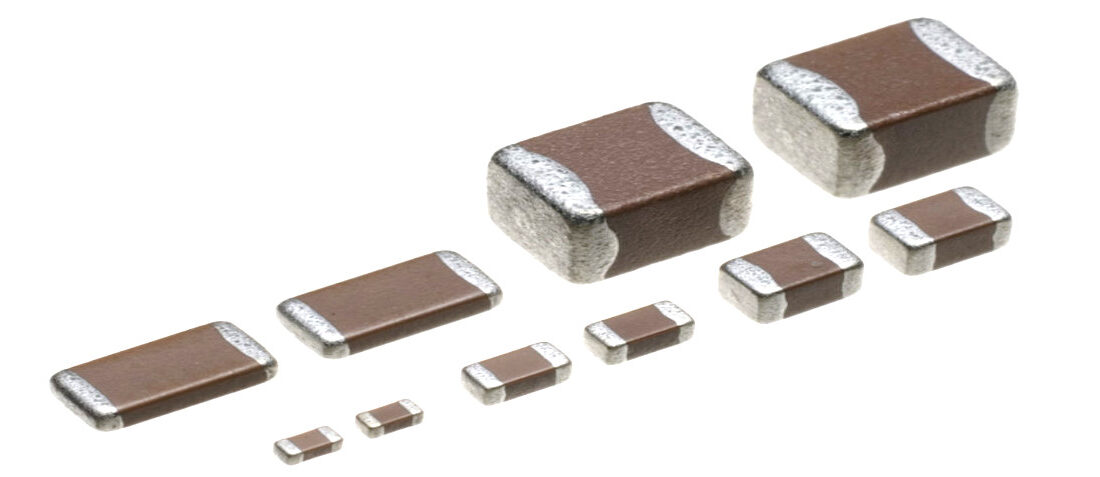

Chip size eia 1206 3 2 1 6 1 5 mm. Increasing the dielectric constant improving the temperature dependence of the characteristics and designing the highly reliable ceramics were the principal focus for the material design engineers. Its temperature variation of capacitance is within 15 from 55 c to 125 c. The rate of aging of class 2 capacitors mainly depends on the materials used.

The bx dielectric is limited to 15 maximum change in capacitance between.