Temperature Profile For Firing Ceramics

You cannot fire pottery in a home oven because ovens do not get up to the high temperatures of more than 1 500 degrees fahrenheit that you need for firing clay.

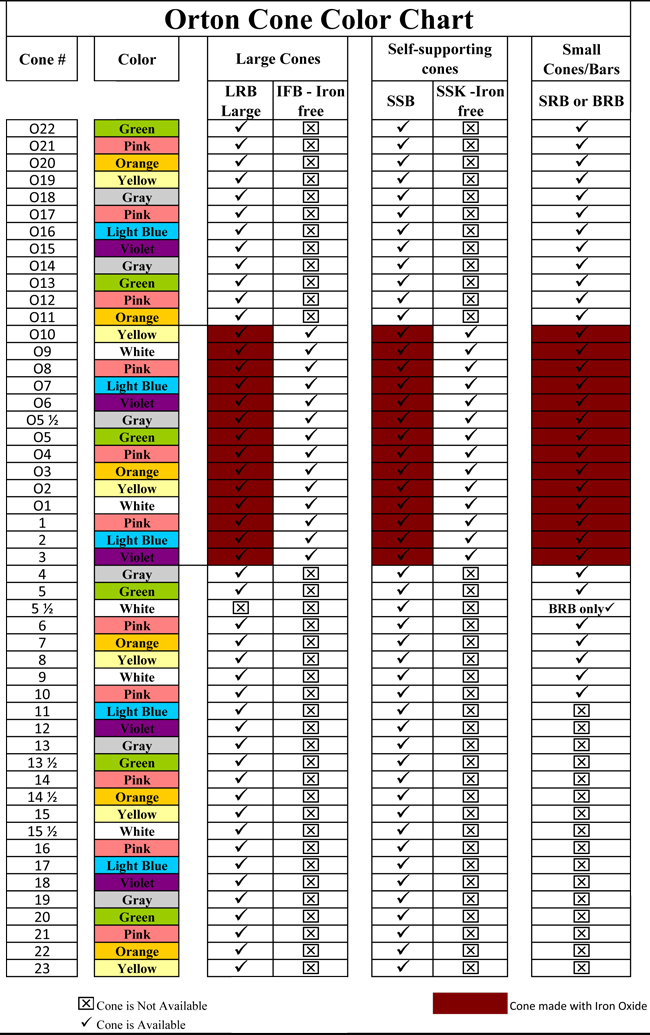

Temperature profile for firing ceramics. The name biscuit firing or bisque firing as it s sometimes known is given to the very first firing of pottery before it is glazed. In the first firing stage a kiln is heated from room temperature to just short of the boiling temperature of water at that location. The ware is returned to the kiln for a very low temperature firing in order to fuse the. Stoneware glaze some decals fire to cone 10.

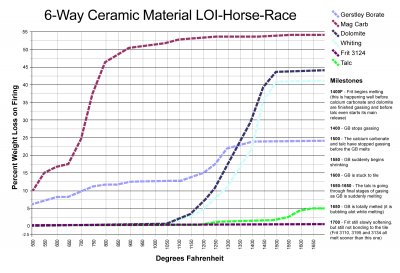

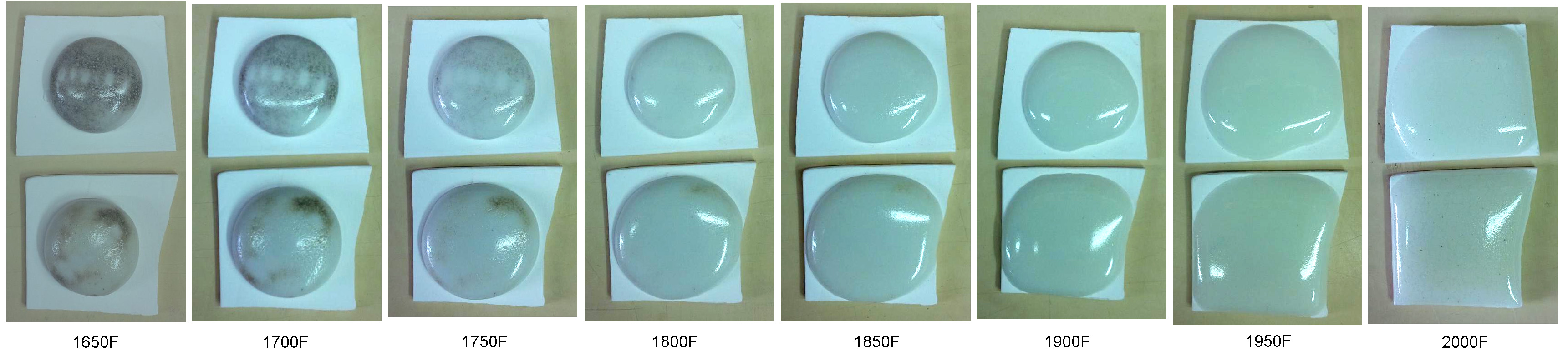

Low fire mid range and high fire ranges. Because the bisque firing has already changed the clay into the ceramic material glaze firings can increase temperatures faster at the beginning and middle of the firing. Ware and glaze types. Potters need to know the processes taking place in order to be able to control the outcome.

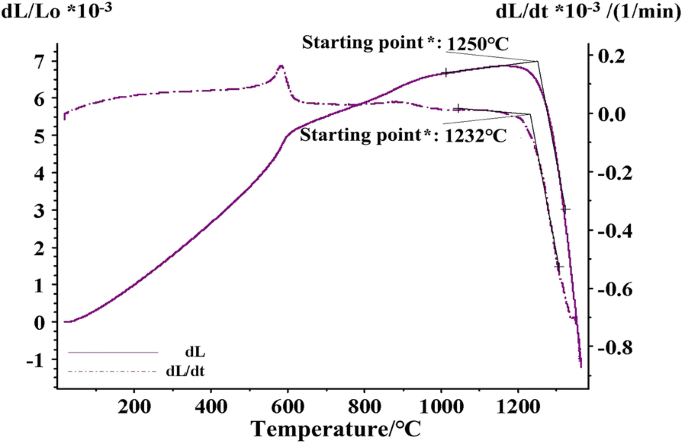

For this example we ll also see that the kiln will be down fired. As well as firing clay the glaze must also be fired to maturity. When the ceramic piece is finished it is called greenware. For mid range material a kiln should be firing at a temperature between 2124 and 2264 1162 1240.

Ceramics must be fired to make them durable. Mid fire earthenware should be fired between cone 2 and cone 7. Very low fire and lower mid range firing ranges. With datapaq kiln tracker system comprised of insight software tp21 data logger selection of protective thermal barriers and thermocouples you gain a.

Most pottery goes through a bisque firing and is then fired again to melt the glaze and fuse it to the clay body bisque firing pottery is the most popular type of firing and is extremely important. A cone 04 glaze firing schedule with down firing. It is cleaned allowed ample drying time and cooked in a high temp oven called a kiln. The temperature needed to transform soft clay into hard ceramic is extremely high and is usually provided by a kiln.

In regards to glazes we need to add two other ranges. At this stage the ceramic piece is either painted with acrylic paint or glazed. Mostly yellow with a hint of orange. The type of kiln used.

The process of firing ceramic ware then glazing it and firing it again to obtain the finished or sometimes intermediate product. This stage is called bisque. When potters talk about ceramic firing ranges they are usually referring to the three most common. When the ceramics finish the first firing they are hard dry and strong.

The heat will be applied just enough to slow the cooling.