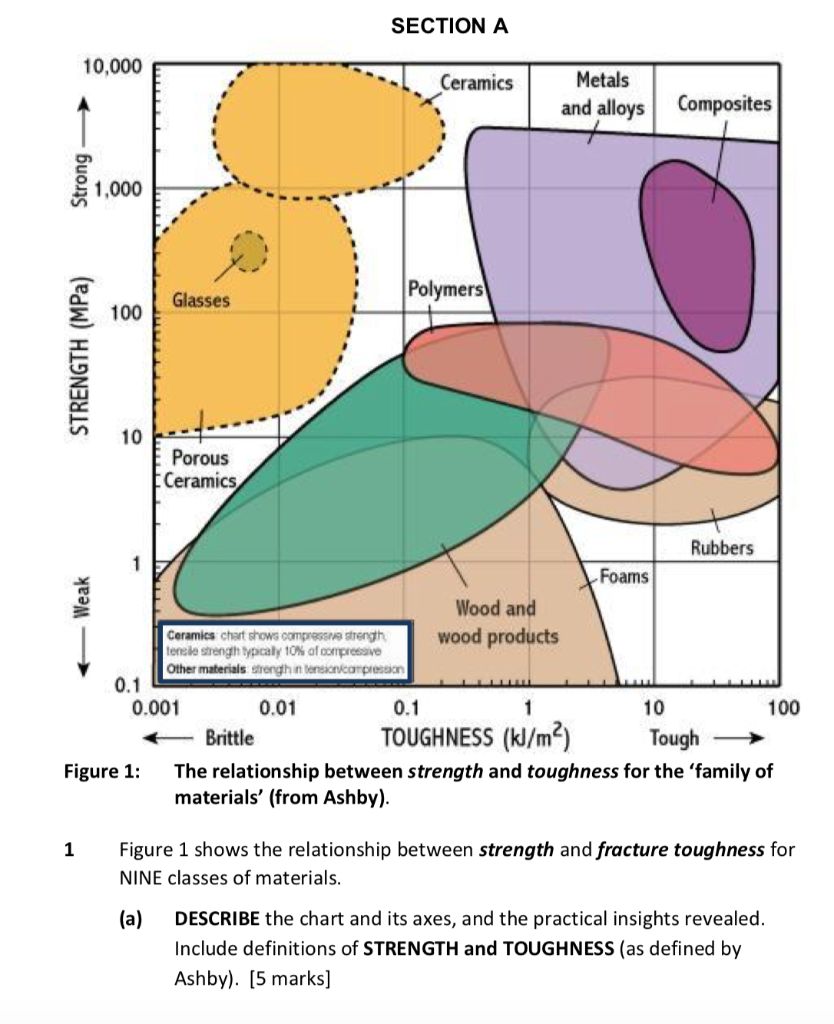

Tensile And Compressive Strength Of Ceramics

In the study of strength of materials tensile strength compressive.

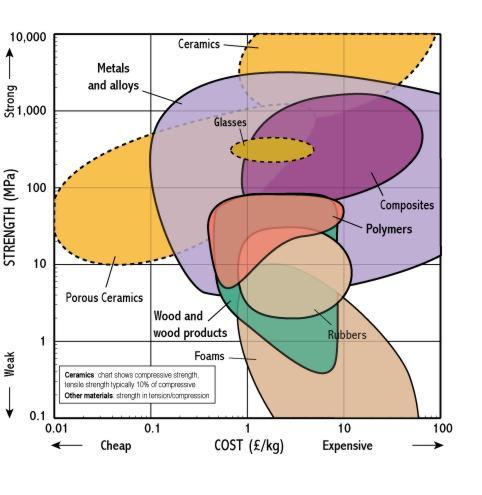

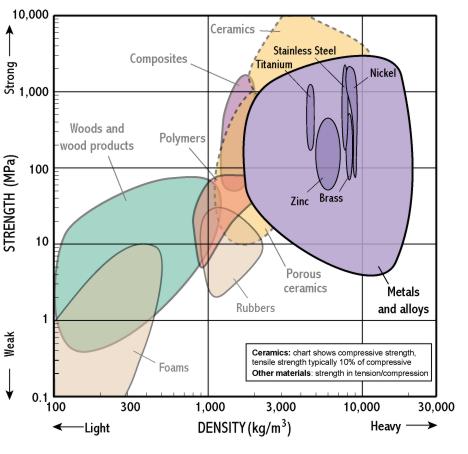

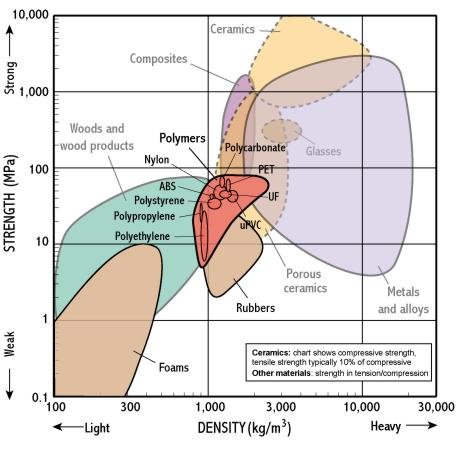

Tensile and compressive strength of ceramics. Maximum safe operating temperature o c thermal conductivity k 10 3 cal cm sec o c tensile strength σ psi compressive strength σ psi flexural strength σ psi modulus of elasticity e 10 6 psi. Why is the tensile strength of ceramics much lower than. Although tensile strength distributions of ceramics are probabilistic and can be described by a weakest link failure theory such descriptions have been shown to be inapplicable to compressive strength distributions in at least one study 1. Properties of some common ceramics.

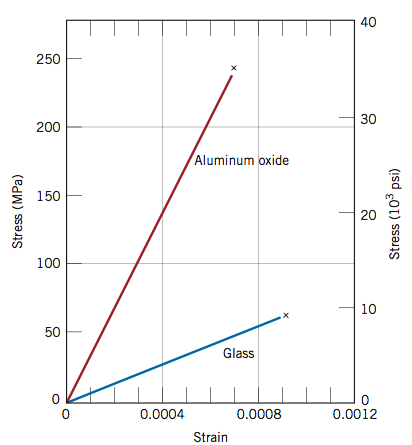

Usually ceramic strength is tested using a four point bend test. The discrepancy between tensile and compressive strengths is in part due to the brittle nature of ceramics. Compressive strength or compression strength is the capacity of a material or structure to withstand loads tending to reduce size as opposed to which withstands loads tending to elongate. In other words compressive strength resists being pushed together whereas tensile strength resists tension being pulled apart.

Different types of ceramics products are available in the market which are being used for a wide variety of applications. Alumina for example has a tensile strength of 20 000 psi 1138 mpa while the compressive strength is 350 000 psi 2400 mpa. Ceramics tend to be weak in tension but strong in compression. Bricks tiles sanitary wares sewer pipes pottery etc.

When subjected to a tensile load ceramics unlike metals are unable to yield and relieve the stress. Ceramics have compressive strengths about ten times higher than their tensile strength. The initial stress for crack growth under uniaxial compression ai is also shown in the figure. 3 however the need to test a statistically significant number of compressive test specimens is not.

Ceramics typically have good tensile strengths and are used under compression e g. Figure 11 shows the actual fracture criterion under the tension compression quadrant for silicon nitride sn 73 for which the tensile strength is 0 481 gpa the compressive strength is 5 68 gpa and the ratio k is assumed to be 1 2. Ceramics tend to be weak in tension but strong in compression. Are the common examples of ceramic products.

The tensile strength of ceramics and glasses is low because the existing flaws internal or surface cracks act as stress concentrators. The wastes generated from.