The Ceramic Process 6 1 Different Stages Of Drying

The basic steps include raw material procurement beneficiation mixing forming green machining drying presinter thermal processing glazing firing final processing and packaging.

The ceramic process 6 1 different stages of drying. The clay will still dry under the bags but at a slower rate. Clays exhibit plasticity when mixed with water in certain proportions. To prevent pieces from drying too fast cover with either dry cleaning grocery or garbage bags. However when dry clay becomes firm and when fired in a kiln permanent physical and chemical changes occur these changes convert the clay into a ceramic material.

11 7 2 process description1 3 5 figure 11 7 1 presents a general process flow diagram for ceramic products manufacturing. Wrap handles and rims with plastic to help equalize drying. 2 fill the right amount of water in the blunger. Generally convection drying is the most commonly used method in which heated air is circulated around the ceramic piece that alleviates the risk of such imperfections in the final product.

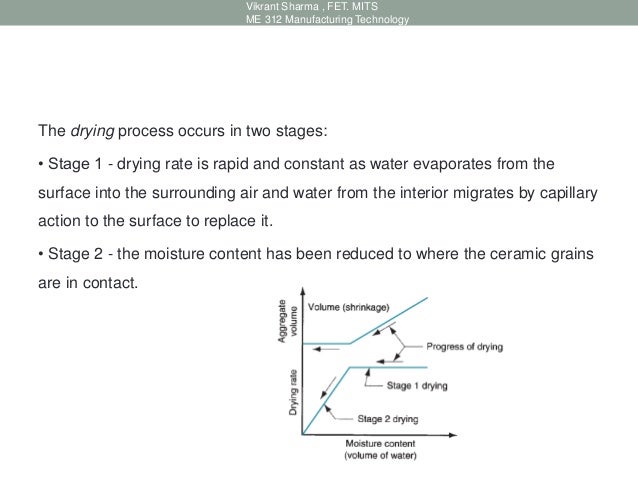

Stage 2 the moisture content has been reduced to where the ceramic grains are in contact. Sulfates can be neutralized by additions of barium carbonate usually 0 2 1. Drying process separate in two part 1. Uneven drying can lead to warping or cracking in your piece.

The cooling for this system is provided by the qeas. Drying ceramics without cracks description. We will discuss all the production process methods used in the. Stage 1 drying rate is rapid and constant as water evaporates from the surface into the surrounding air and water from the interior migrates by capillary action to the surface to replace it.

Drying is the most energy consuming process in ceramic tiles industries. 1 dry all body materials and weigh them accurately. Drying with the dryer 2. There are different production process methods are used in the ceramic production process.

The air drying process in the integrated multigeneration system follows psychrometric processes of cooling and dehumidifying as shown in figure 14 15. Anything ceramic ware can be dried if it is done slowly and evenly enough. When drying pottery place a plastic cover over your pots. Dry pots upside down to even out the drying process.

Because of these properties clay is used for making pottery both utilitarian and decorative and construction products such as bricks walls and floor tiles. The drying process occurs in two stages. To dry faster optimize the body recipe ware cross section drying process and develop a good test to rate drying performance. First published in 2008.

Important process of ceramic tlies industries is drying process. Drying the formed materials hold water and binder in its mix that can in turn cause shrinkage warping or distortion of the product. This will prevent a lot of cracking and warping during the drying stage.